Hydraulic power units (HPUs) are versatile machines with a wide range of applications across many industries. HPUs use pressurised hydraulic fluid to generate power to operate hydraulic machinery and equipment.

How Hydraulic Power Units Work

The core components of an HPU are a reservoir, pump, valves, and actuator. Hydraulic fluid is held in the reservoir. An electric motor drives a pump which pressurises the fluid. Control valves regulate the flow and direction of the hydraulic fluid. The pressurised fluid is sent through hoses to a hydraulic cylinder or motor. This actuator provides the linear or rotary motion to do work. For example, extending a cylinder to lift a heavy load. The system allows precise control of large forces.If you want to know more about understanding hydraulic power units: learn more here.

Manufacturing Applications

HPUs have long been a core component of manufacturing processes and factory machinery. They provide the power needed to operate presses, injection moulding machines, lifting equipment, conveyors, and more. Key benefits include the ability to generate high forces and precise control, making HPUs ideal for tasks that require power, speed, and accuracy. HPU systems can be designed for the specific needs of the manufacturing process. Major manufacturing sectors using HPUs include automotive, aerospace, consumer goods, pharmaceuticals, and food production. HPUs enable automation and mass production capabilities that are essential for modern manufacturing.

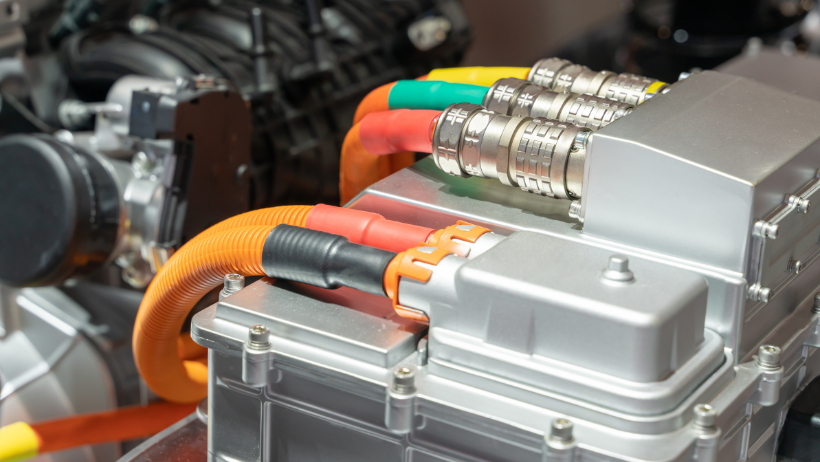

Motorsport Uses

Motorsport relies heavily on HPUs to operate critical systems on high-performance vehicles. In Formula 1 and other categories, HPUs power elements such as the gearbox, power steering, braking, and suspension systems. They allow for adjustable control and rapid responses when driving at high speeds. The hydraulic fluid can be quickly directed to where it is needed. HPUs must be extremely durable and reliable to withstand race conditions. Leading F1 teams use bespoke HPUs, finely tuned for their specific cars and demands. HPUs are also common in rally cars and motorbikes for precision control.

Marine Applications

On ships and boats, HPUs perform numerous duties including powering steering systems, stabilisers, anchoring equipment, lifting gear, and ramps. Reliable hydraulic power is essential when manoeuvring large vessels or operating deck machinery. Marine HPUs must resist corrosion from saltwater exposure, so stainless steel components are often used. Key users include commercial ships, ferries, cruise liners, cargo carriers, fishing fleets, and luxury yachts. Compact HPUs are found on smaller private boats for smooth and responsive steering.

Aerospace Uses

In aircraft, HPUs provide power for various flight control surfaces, landing gear, brakes, and cargo doors. Reliability is critical, as an HPU failure could have catastrophic consequences. Aerospace HPUs must meet stringent standards, tolerating extreme temperatures and vibrations. Leading applications include flap and slat actuators, thrust reversers, and wheel brakes. Both civil and military aircraft depend on HPUs during flight and ground operations. Custom HPUs are designed for specific aircraft needs.

From precision manufacturing on the factory floor to performing under race conditions, HPUs demonstrate their flexibility across sectors. With responsive hydraulic power and control, they meet the diverse needs of industries from automotive to aerospace. Continuing advances in HPU technology will open up further possibilities in future.